Introduction to Apple’s Production Plans

On the heels of Vice President JD Vance’s visit to India, a recent report indicates that Apple aims to shift the production of all U.S.-bound iPhones to India by the end of 2026. This move is largely in response to the global trade war initiated by President Trump, which has seen China facing tariffs of over 100% on imports to the U.S., although smartphones currently incur a lower tariff of 20%.

Tariffs and Their Implications

India, on the other hand, is subject to 26% "reciprocal" tariffs, which are temporarily paused as the administration negotiates a trade deal. According to the Financial Times, achieving the goal of manufacturing 60 million smartphones in India would necessitate doubling Apple’s current output in the country over the next two years. Apple initially started building iPhones in India in 2017 as a strategy to diversify its supply chain, especially after China’s COVID-era lockdowns affected production. However, the company primarily focused on lower-end models in India, and China has remained central to Apple’s business.

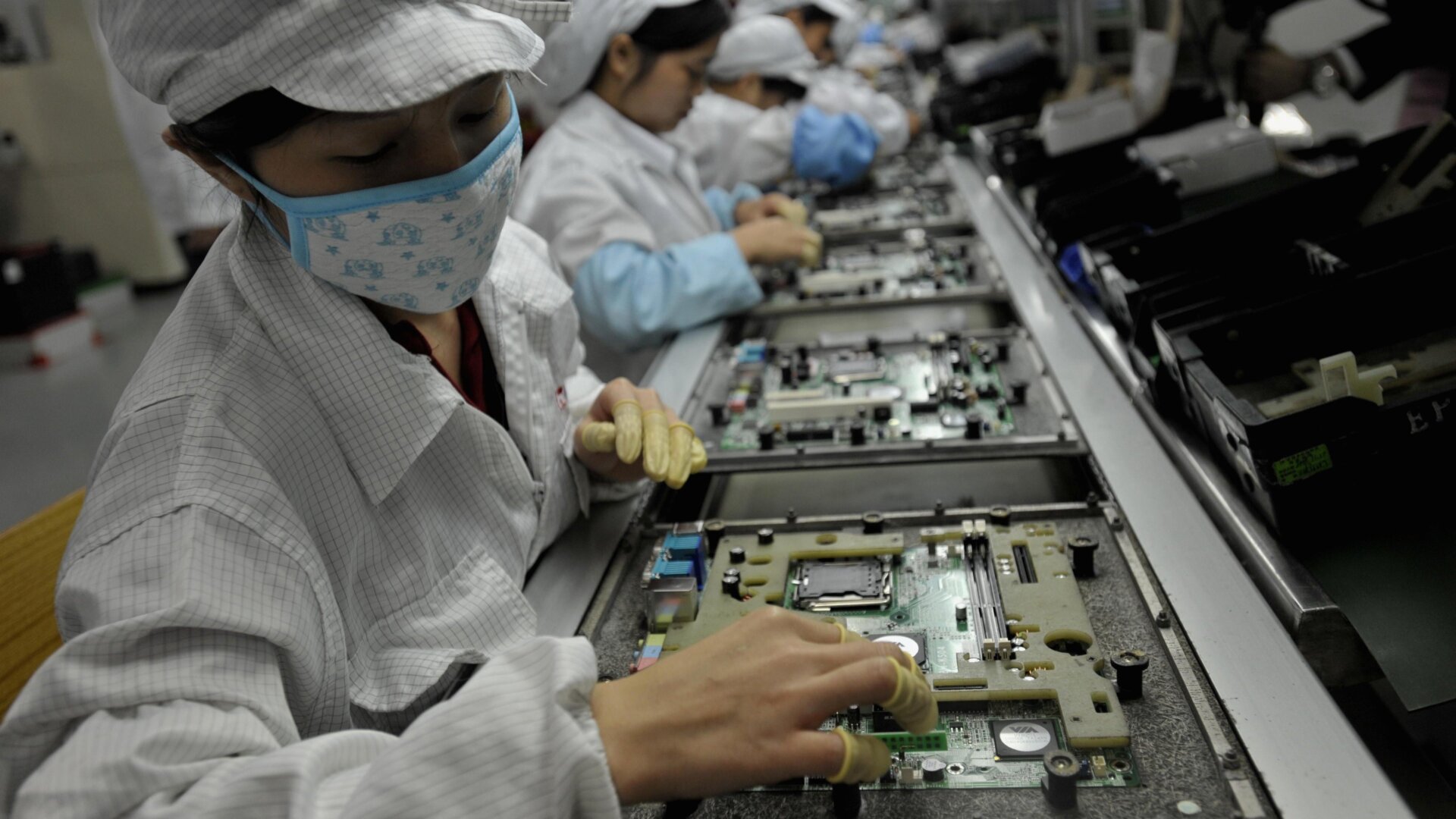

Manufacturing vs. Component Production

A crucial point to consider is that Apple is moving its iPhone assembly to India, not the production of components. This means that all parts will still be sourced from China and Taiwan and then shipped to India for assembly. This undermines the notion of bringing manufacturing jobs back to the U.S., as envisioned by Commerce Secretary Howard Lutnick. The idea of Americans assembling iPhones is not imminent, as the "army of millions and millions of human beings screwing in little screws to make iPhones" is not coming to the U.S. anytime soon.

Challenges in Manufacturing

Tim Cook has emphasized that manufacturing in China is not solely about cost savings but also due to the country’s advanced manufacturing skills. Although China has lost its price advantage over the years as wages have increased, and some companies have moved manufacturing to other locations like Vietnam, the supply chain remains deeply entrenched in China. This includes components such as enclosures, packaging, small parts, and rare earth metals, making it challenging to manufacture electronics elsewhere.

Impact of Tariffs on Consumers

If tariffs on India remain in place, it could lead to more expensive iPhones for American consumers, with little benefit to the U.S. economy. Early revenue from President Trump’s tariffs has been lower than anticipated, according to Customs and Border Patrol reports. While companies like Apple may be willing to move away from China, manufacturing in the U.S. remains a long-term goal that would take years to achieve, and domestically made products would likely be less competitive with foreign-built alternatives.

The Reality of Global Trade

The United States excels in services such as designing chipsets and social networking platforms, leaving the labor-intensive manufacturing work to countries adept at these functions. Unfortunately, President Trump’s perspective on trade is based on a fallacy that each transaction has a winner and a loser. In reality, trade is a mutually beneficial exchange where one country provides cash, and the other returns a desired product. The U.S. economy has experienced decades of growth, indicating that the trade system is functioning well.

Room for Improvement and Automation

While there are areas for improvement, such as reducing reliance on cheap labor from abroad and potentially manufacturing key products like computer chips domestically, Apple has committed to investing $500 billion in American manufacturing, focusing on building servers and data centers. However, the push for domestic manufacturing could lead to an economy plagued by inflation and fewer jobs in manufacturing than anticipated, especially as companies like Amazon continue to automate their operations.

Conclusion

In conclusion, the idea of bringing iPhone manufacturing back to the U.S. is not feasible in the current landscape. Americans are not eager to fill manual labor jobs, and the move towards automation will likely continue. The pursuit of reshoring manufacturing could ultimately harm the economy, leading to inflation and reduced employment opportunities in the manufacturing sector.

Source Link